The team is designing a bridge to span tram lines 4, 8 and 9 at Alelyckan, located between Gamlestaden and Hjällbo. The assignment includes the development of a permanent structure over the tramway in the form of a trough and a bridge. A trough is a recessed structure consisting of two retaining walls with a common base slab, intended to carry traffic within the space between the walls. Inhouse Tech has also designed a culvert to enable the diversion of an essential pipeline that forms part of Gothenburg’s drinking water supply.

In addition to the bridge and the culvert, a temporary slab was constructed to support a portal spanning the tramway, enabling preparatory works for the casting to proceed while tram traffic remained operational. Only three traffic-free weekends were required to complete the work on the bridge: one weekend to erect the portal, one to cast the superstructure (bridge deck) and one to dismantle the portal. The portal thereby allowed tram services to continue throughout the entire construction period. The portal and its scaffolding were designed by another company.

Inhouse Tech’s involvement commenced in March 2024. The casting of the bridge deck was carried out on 17 June 2025. According to Trafikverket, the stabling facility in Lärje is expected to be completed by 2027.

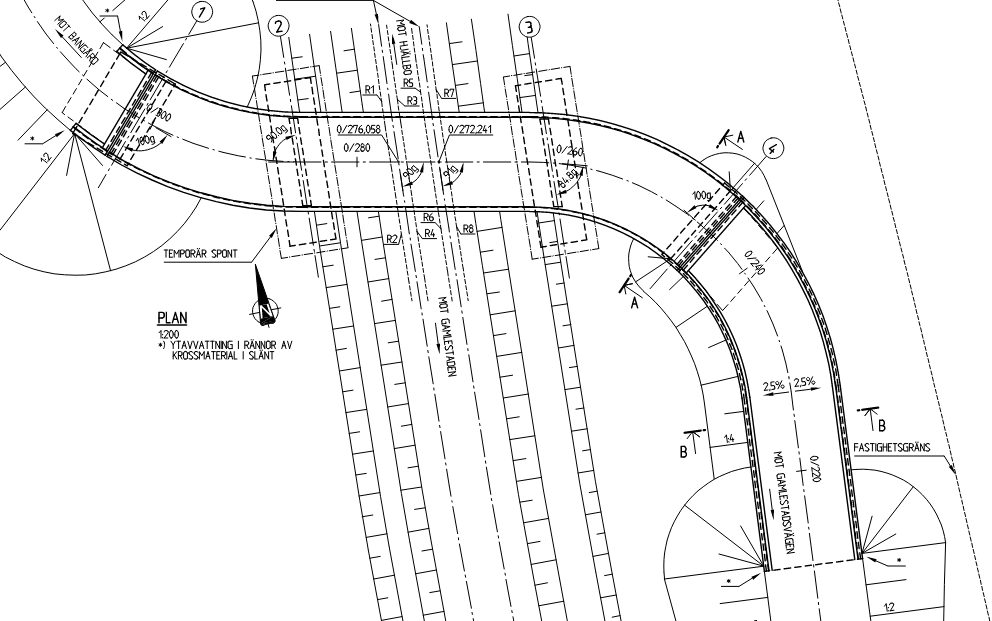

“The main difficulty has been the S-shaped geometry in plan together with a vertical radius. The formwork and reinforcement works have posed the biggest challenge given this type of design,” says

Due to challenging ground conditions and ongoing settlements, only vertical piles were employed to found the structures in this case. Inclined piles would have been subjected to substantial lateral forces from the clay masses, which would have significantly reduced their vertical load-bearing capacity. The horizontal loads are instead resisted by the friction between the soil and the piles as well as the slabs. The bridge is a continuous slab bridge supported on four bearings, and in plan it has an S-shaped geometry, which is unusual.

“The distinctive S-shape of the bridge combined with the vertical piles has been the greatest challenge in the project,”

An interesting aspect of the initiative is the focus on sustainable materials management, with Leca material from the E6 landslide in September 2023 being reused. This both reduces costs and minimises environmental impact, as the material can be repurposed instead of being sent to landfill. Before being placed at its new location, the material undergoes quality control to ensure proper integration.

Would you like to learn more about the project or our services within bridge design? Please contact us at Inhouse Tech!